Hi everyone,

I am trying to establish a FEM Model of a cylindrical battery. This should be done with SOLID elements only.

The idea is to have concentric circles with repeating PIDs, let's call it just PIDs 1,2,1,3,4,5,4,3,1,2,1,3,4,5,4... and so on. The logic can be defined easily by me.

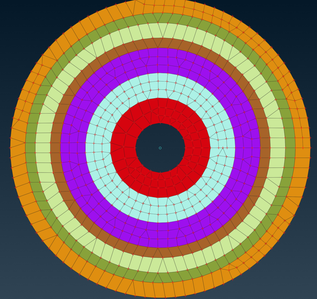

I have tried a view ways with ANSA without much success yet. So something like this:

But there are still quite few issues:

I create 2 curves for each layer, merge the curves, fill with a face, extrude it. Thus the elements are not very nice, and on the "fusion" of the face there is a line with duplicate nodes.

I thought about using solid_builder instead, but it does not really work with scripting.

Does anyone have another idea?

For hex meshing, you generally want to find the best way to work from a source face to a target face. In this case, it would be best to work from one end of the tube to the other. So start with meshing each layer with a shell quad mesh and organize it radially so it looks "nice". Then you can control how many elements thick you want each layer to be and you'll be able to keep a consistent meshing structure.

If you do keep the number of elements radially for each layer consistent, the elements of you layers in the innermost portion of your cylinder will have much smaller edge lengths than the outermost. This might cause issues with your solution if those element aspect ratios get too skewed. It can also affect any mass scaling.

Have you considered using TrueGrid to mesh this? I would suggest projecting each layer to the surface of concentric cylinders and build each layer from a different cylinder wedge part. Use transitions to reduce the number of elements as the rings get smaller. Form block boundaries and merge collateral nodes between layers. Once your wedge is complete, replicate it to form the full cylinder. They have a free trial and training videos to help you learn.