Beginner’s Guide to Finite Element Analysis

Have you ever wondered how engineers make sure bridges won’t collapse or how car manufacturers know their vehicles will be safe in a crash? One of their most powerful tools is something called Finite Element Analysis, or FEA for short. Don’t worry if that sounds intimidating – we’re going to break it down into simple pieces that anyone can understand!

What is Finite Element Analysis?

Imagine you’re trying to figure out if a diving board at a pool will break when someone jumps on it. You could try to calculate this using one big mathematical equation, but that would be incredibly complex. Instead, FEA takes a clever shortcut: it breaks the diving board into many small, simple pieces (called “elements”) and analyzes each one separately. It’s like solving many small puzzles instead of one giant one!

The Basic Steps

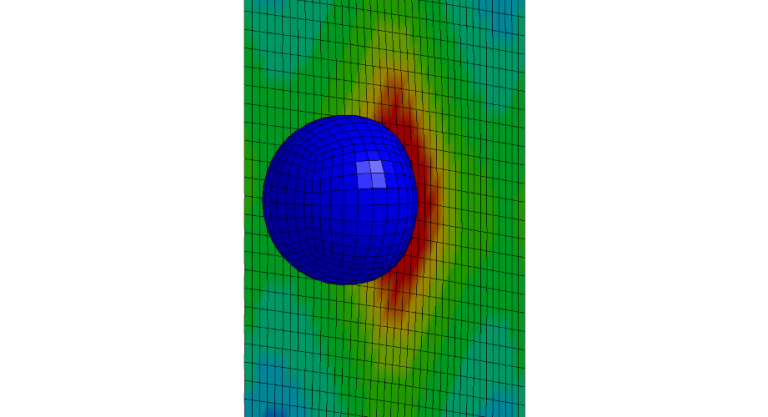

- Breaking Things Down (Meshing)

- First, we take our object (like that diving board) and divide it into smaller pieces

- These pieces can be triangles, squares, or other simple shapes

- The smaller and more numerous the pieces, the more accurate our analysis will be

- Engineers call this divided version a “mesh” because it looks like a net

- Setting the Stage (Boundary Conditions)

- We tell the computer what’s happening to our object

- Where is it fixed? Where are forces being applied?

- In our diving board example:

- One end is firmly attached to the pool deck

- Someone’s weight is pushing down on the free end

- Solving the Problem Simulation

- The computer calculates how each small element responds to the forces

- It makes sure all the pieces work together properly

- This gives us important information like:

- How much the object will bend

- Where it might break

- Which areas are under the most stress

Real-World Applications

FEA isn’t just for diving boards! It’s used in countless situations:

- Automotive: Optimize vehicle structure to absorb energy in a crash

- Buildings: Making sure skyscrapers can withstand earthquakes and storms

- Medical Devices: Designing better prosthetic limbs

- Consumer Products: Testing if your phone will survive being dropped

- Aerospace: Ensuring airplane wings can handle extreme conditions

Why FEA Matters

Think of FEA as a virtual testing ground. Instead of building multiple prototypes and breaking them (which would be expensive and time-consuming), engineers can use computers to:

- Test designs before building anything

- Find and fix problems early

- Try out different materials

- Optimize designs to use less material while retaining strength

- Save time and money in the development process

Limitations and Common Misconceptions

Like any tool, FEA isn’t perfect:

- Results are only as good as the input data

- It’s an approximation, not an exact solution

- Expert knowledge is still needed to interpret results

- Real-world testing is often still necessary

Getting Started with FEA

If you’re interested in learning more, here are some ways to begin:

- Start with simple 2D problems

- Learn basic engineering principles first

- Practice with free FEA software like FreeCAD or student versions

- Focus on understanding the physics behind the problems

- Join online communities and forums for support (like ours!)

Final Thoughts

Finite Element Analysis might seem like magic, but it’s really just a clever way of breaking big problems into manageable pieces. Whether you’re designing the next revolutionary product or just curious about how things work, understanding FEA basics can open up a whole new way of thinking about engineering problems.

Remember: every expert started as a beginner, and even the most complex analyses begin with these fundamental concepts. Happy analyzing!

Have a question or comment? Join the discussion here.