Hello Everyone!

I have some trouble with understanding the simulation behaviour from the picture, I hope some of you would you be so kind to help me out.

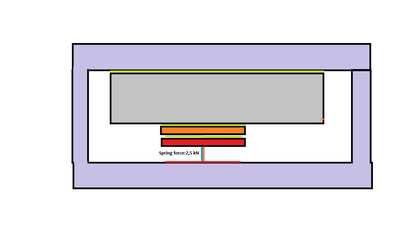

I'm using LsDyna explicit (r12.2). I have a spring pretension in the model (blue line), with 2,5 kN initial load, after it moves ~0,2 mm, it is stabilizing at ~ 2,3 kN. I'm using Beam type 68 and a General_Spring_Discrete_Beam (type196) material, and I added a Translational joint (orange line) to have only axial movement. The beam and the joint are attached to a pushing pad (red part) and to the Aluminum part with constrained nodal rigids (the whole pushing pad is rigid). After the pushing pad, the orange part is a plastic part, and above that a steel part. My issue is, that I only measure ~900N in all of the contacts (green lines, automatic surface to surface contact, soft 2). Shouldn't they be the same as the spring force? There is a small yielding in the plastic part, but after I changed it to rigid, it is only an extra 60N in the contact forces. I also tried different values of the stiffness scaling factors and viscous damping factors on the contact pairs, but I couldn't get higher contact forces than that.

Does any of you any idea, what is the reason behind this force difference?